Manual power poles are essential for supporting utility cables and equipment, serving as critical infrastructure for reliable power distribution in modern society. They ensure consistent energy supply, making them indispensable in both urban and rural settings.

1.1 What is a Manual Power Pole?

A manual power pole is a tall, sturdy structure designed to support utility cables, such as electrical and telecommunications lines. Made from materials like wood, steel, or concrete, it plays a crucial role in distributing power and connecting services to homes and businesses, ensuring reliable energy delivery.

1.2 Importance of Manual Power Poles in Modern Infrastructure

Manual power poles are foundational elements in modern infrastructure, supporting utility cables and enabling reliable power and communication services. They ensure consistent energy delivery, underpinning daily life, economic activities, and technological advancements, making them indispensable for societal functioning and progress.

History and Evolution of Manual Power Poles

Manual power poles trace their origins to the 1800s, evolving from wooden telegraph poles to modern engineered structures. The 1924 invention of the Stobie pole marked a significant milestone, enhancing durability and versatility for utility applications.

2.1 Early Development and Historical Context

The earliest power poles emerged in the 19th century, primarily for telegraph lines, using untreated wood. As demand for electricity grew, so did their design, with treated materials and standardized sizes becoming common by the early 20th century, laying the groundwork for modern utility systems.

2.2 Key Milestones in the Evolution of Power Poles

The invention of the Stobie pole in 1924 marked a significant advancement, offering durability and versatility. Transition from wood to concrete and steel poles improved longevity. Modern innovations include smart technologies for real-time monitoring and load management, enhancing efficiency and reliability in power distribution systems globally.

Design and Construction of Manual Power Poles

Manual power poles are crafted from durable materials like wood, concrete, and steel, ensuring longevity and strength. Their design prioritizes stability, with engineering focused on withstanding environmental stresses and heavy loads while integrating safety features for reliable performance.

3.1 Materials and Engineering Considerations

Manual power poles are typically made from wood, concrete, or steel, chosen for their strength and durability. Engineering focuses on load-bearing capacity, environmental resistance, and longevity, ensuring they can withstand harsh weather and heavy use while maintaining structural integrity and reliability over time.

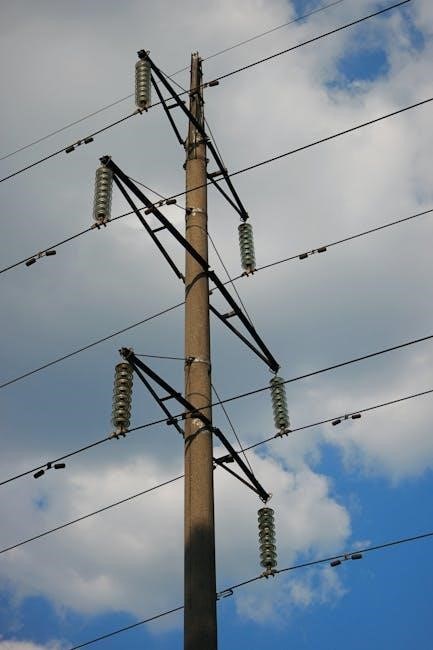

3.2 Components of a Manual Power Pole

A manual power pole consists of a sturdy shaft, crossarms, insulators, conductors, and grounding wires. The shaft provides structural support, while crossarms hold insulators and conductors. Insulators prevent electricity leakage, and conductors transmit power. Grounding wires ensure safety by directing surges away, protecting both the system and users from potential hazards.

3.3 Safety Features in Design

Manual power poles incorporate safety features like insulators to prevent electrical conduction, grounding wires for surge protection, and durable materials to withstand harsh conditions. These designs adhere to strict safety standards, ensuring reliability and minimizing risks of electrical hazards, while also protecting against environmental stresses and potential failures.

Installation and Maintenance of Manual Power Poles

Manual power poles require precise installation, ensuring stability and alignment. Regular maintenance involves inspections, repairs, and upgrades to uphold functionality and safety standards over time.

4.1 Step-by-Step Installation Process

Begin with site preparation, ensuring the area is clear. Dig holes to the required depth, then set the pole, aligning it properly. Secure it with concrete, allowing it to cure. Connect cables and hardware, ensuring safety and stability. Conduct final inspections to verify proper installation and functionality before commissioning.

4.2 Regular Maintenance Requirements

Regular inspections are crucial to identify wear and tear, ensuring safety and functionality. Cleaning insulators, checking connections, and lubricating mechanical parts are key tasks. Timely repairs prevent failures, while adhering to safety regulations ensures reliability and extends the lifespan of manual power poles in various applications.

4.3 Tools and Equipment Needed

Essential tools include post-hole diggers, concrete mixers, and anchor installation kits. Safety gear like harnesses and gloves is mandatory. Testing equipment such as multimeters ensures proper electrical connections. Specialized wrenches and lubricants are also required for secure installations and ongoing maintenance of manual power poles.

Safety Considerations and Regulations

Adherence to safety guidelines is crucial, emphasizing proper handling and PPE use. Compliance with OSHA standards ensures worker protection, while regular inspections prevent hazards and maintain reliable power distribution.

5.1 Safety Best Practices for Handling Manual Power Poles

Always wear proper PPE, including gloves and hard hats; Follow OSHA guidelines for lifting and handling heavy equipment. Ensure the area is clear of obstacles and bystanders. Use correct lifting techniques to avoid injuries. Regularly inspect equipment for damage before use. Secure the pole firmly during transport to prevent accidents.

5.2 Relevant Safety Regulations and Standards

Adhere to OSHA guidelines for utility pole safety, ensuring compliance with ANSI and NESC standards. These regulations outline requirements for equipment, installation, and maintenance to prevent accidents. Regular inspections and updated certifications are crucial for maintaining safety protocols and industry standards.

5.3 Emergency Procedures and Protocol

In case of emergencies involving manual power poles, immediately evacuate the area and contact utility authorities. Disconnect power if safe to do so. Avoid downed lines and use safety equipment. Follow established emergency response plans to ensure public safety and prevent further damage or hazards.

Environmental Impact of Manual Power Poles

Manual power poles can affect ecosystems due to placement and material use. Environmental considerations in their installation help mitigate ecological disruption, promoting sustainable infrastructure development.

6.1 Environmental Considerations in Placement

Strategic placement of manual power poles minimizes ecological disruption. Assessing local ecosystems ensures poles avoid sensitive habitats. Placement considers soil stability, vegetation, and wildlife corridors to reduce environmental impact and support conservation efforts effectively.

6.2 Mitigation Strategies for Environmental Impact

Implementing eco-friendly materials and sustainable practices reduces environmental impact. Strategic planning minimizes habitat disruption, while noise reduction measures protect wildlife. Regular inspections and maintenance ensure longevity, reducing the need for frequent replacements and further ecological disturbance.

6.3 Sustainability and Eco-Friendly Alternatives

Manual power poles can adopt eco-friendly materials like recycled steel or sustainable wood. Innovations include integrating smart technology for energy efficiency and using renewable energy sources. These alternatives reduce environmental footprint while maintaining reliability, aligning with global sustainability goals.

Applications in Different Industries

Manual power poles are widely used in telecommunications, electrical distribution, and transportation. They support infrastructure, enabling reliable communication, power supply, and lighting systems across various sectors.

7.1 Use in Telecommunications

Manual power poles play a crucial role in telecommunications by supporting cables, antennas, and other equipment. They enable reliable communication networks, internet connectivity, and mobile services, ensuring seamless data transmission and connectivity across various regions and communities.

7.2 Role in Electrical Distribution

Manual power poles are foundational to electrical distribution systems, supporting transformers, wires, and other equipment. They ensure reliable power delivery from substations to consumers, maintaining grid stability and safety while managing voltage levels effectively across urban and rural areas.

7.3 Applications in Transportation and Other Fields

Manual power poles are integral to transportation systems, supporting traffic lights, road signs, and public transit infrastructure. They also serve in maritime environments for docking lights and in construction zones for temporary power solutions, showcasing their versatility beyond traditional utility applications.

Manual vs. Hydraulic Power Poles

Manual power poles offer simplicity and lower costs, while hydraulic systems provide faster operation and automation, each suited for specific applications based on efficiency and resource needs.

8;1 Comparison of Manual and Hydraulic Systems

Manual power poles are simple, cost-effective, and manually operated, ideal for shallow waters and specific applications. Hydraulic systems offer faster, automated operation but are more complex and expensive. Each system has unique advantages, making them suitable for different operational needs and environments.

8.2 Advantages and Disadvantages of Each

- Manual power poles are cost-effective, simple, and reliable, requiring minimal maintenance. They are ideal for shallow waters and specific applications.

- Hydraulic systems offer faster, automated operation but are more expensive and complex, requiring regular maintenance.

8.3 Choosing the Right System for Specific Needs

Choosing the right system depends on specific needs. Manual power poles are ideal for simplicity, low cost, and minimal maintenance; Hydraulic systems offer automation and efficiency, suited for heavy-duty applications. Consider factors like budget, application, and maintenance preferences. Environmental conditions and user expertise also play a role. Professional advice ensures optimal selection.

Troubleshooting Common Issues

Manual power poles may face issues like wear, alignment problems, or control malfunctions. Regular inspections and timely repairs are crucial to maintain functionality and safety standards effectively.

9.1 Identifying and Diagnosing Problems

Identifying issues with manual power poles involves inspecting for wear, corrosion, or mechanical faults. Diagnostics may include visual checks, performance testing, and reviewing maintenance records to pinpoint problems accurately, ensuring timely and effective resolutions to prevent operational disruptions.

9.2 Common Issues and Their Solutions

Common issues with manual power poles include wear, corrosion, and mechanical faults. Solutions involve regular lubrication of moving parts, timely replacement of worn components, and proper insulation checks. Addressing these problems early prevents system failures and ensures reliable operation, minimizing downtime and maintenance costs effectively.

9.3 Preventative Measures to Avoid Failures

Regular inspections, lubrication of mechanical components, and corrosion protection are key preventative measures. Ensuring proper installation, adhering to load limits, and timely replacement of worn parts help avoid failures. Routine maintenance schedules and training for handlers also significantly reduce the risk of operational issues and extend the lifespan of manual power poles.

Future Innovations in Manual Power Poles

Future innovations may include smart technology integration, advanced materials, and automated systems. These developments aim to enhance durability, efficiency, and safety, ensuring manual power poles remain vital in modern infrastructure.

10.1 Emerging Technologies and Trends

Emerging technologies include smart sensors, IoT integration, and eco-friendly materials. Trends focus on enhancing durability, energy efficiency, and real-time monitoring. These innovations aim to modernize manual power poles, ensuring they adapt to future demands while maintaining reliability and sustainability in utility distribution systems.

10.2 Potential Advancements in Materials and Design

Advancements include lightweight composite materials, corrosion-resistant coatings, and modular designs. These innovations enhance durability, reduce maintenance, and improve adaptability. Smart materials and integrated sensors could enable real-time monitoring, while eco-friendly designs promote sustainability, ensuring manual power poles remain efficient and reliable in future utility systems.

10.3 The Role of Smart Technology in Future Developments

Smart technology will revolutionize manual power poles through real-time monitoring, predictive maintenance, and automation. Integrated IoT devices enable remote tracking of conditions, reducing failures. Energy-efficient designs and intelligent systems optimize performance, ensuring reliability while minimizing environmental impact, making manual power poles smarter and more sustainable for future energy needs.

Case Studies and Real-World Applications

Manual power poles are essential for supporting utility cables and equipment, serving as critical infrastructure for reliable power distribution in modern society. They ensure consistent energy supply, making them indispensable in both urban and rural settings.

11.1 Successful Projects Utilizing Manual Power Poles

Manual power poles have been instrumental in numerous infrastructure projects, providing reliable support for utility cables and equipment. Their versatility and durability make them a cornerstone in modern telecommunications, electrical distribution, and transportation systems, ensuring seamless connectivity and power supply across diverse landscapes and urban environments.

11.2 Lessons Learned from Large-Scale Implementations

Large-scale manual power pole projects emphasize the importance of detailed planning, environmental considerations, and adherence to safety regulations. They highlight the need for durable materials and efficient installation processes to ensure long-term reliability and minimal maintenance, while also addressing community concerns and integrating with existing infrastructure seamlessly.

11.3 Examples of Innovation in Use

Manual power poles have seen innovative applications, such as the Stobie pole, known for its durability in extreme conditions. Additionally, their use in telecommunications and electrical distribution highlights their versatility. Recent advancements include modular designs for easier upgrades and integration with smart technology, enhancing efficiency and resilience in modern infrastructure systems.

Manual power poles remain a cornerstone of modern infrastructure, ensuring reliable utility distribution. Their durability and versatility make them indispensable, with ongoing innovations promising an even brighter future ahead.

12.1 Summary of Key Points

Manual power poles are essential for modern infrastructure, supporting power distribution and telecommunications. Constructed from durable materials like wood or concrete, they feature components such as insulators and crossarms. Proper installation and maintenance ensure reliability and safety. They play a vital role in connecting communities, balancing functionality with environmental considerations, ensuring dependable service.

12.2 Future Outlook for Manual Power Poles

Manual power poles are expected to evolve with smart technology integration, enabling real-time monitoring and automation. Eco-friendly materials and modular designs will enhance sustainability. These innovations ensure manual power poles remain vital in modern infrastructure, balancing functional efficiency with environmental responsibility for future generations.